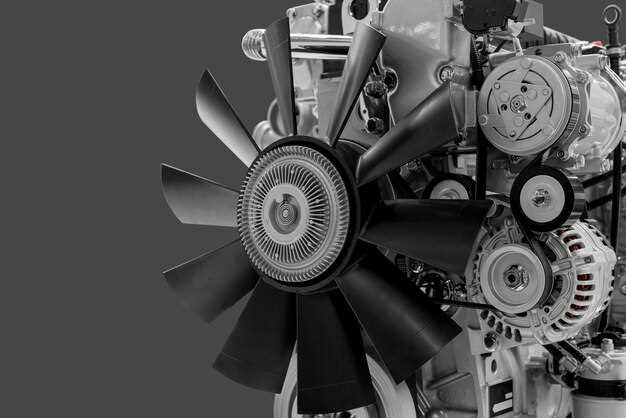

In the realm of automotive engineering, intercoolers play a vital role in enhancing the performance and efficiency of turbocharged engines. These devices serve a critical function by cooling the compressed air generated by the turbocharger before it enters the engine’s combustion chamber. By lowering the air temperature, intercoolers help increase air density, which directly translates into improved engine efficiency and power output.

The fundamental principle behind the operation of an intercooler lies in the relationship between temperature and air density. When air is compressed, as it is in a turbocharged engine, it heats up significantly. Hot air is less dense, meaning it contains fewer oxygen molecules per volume, which can hinder combustion efficiency. An intercooler counteracts this by dissipating the heat from the compressed air, enabling the engine to achieve optimal performance levels.

Various types of intercoolers exist, including air-to-air and air-to-water designs, each with its own set of advantages and applications. Understanding the differences between these systems, as well as the specific requirements of a given engine setup, is essential for any performance enthusiast or automotive engineer looking to maximize the potential of turbocharged engines.

How Intercoolers Improve Turbocharged Engine Performance

In turbocharged engines, intercoolers play a crucial role in enhancing performance and efficiency. When air is compressed by a turbocharger, its temperature rises significantly. This hot, compressed air is less dense and contains less oxygen, which can hinder engine performance. An intercooler helps mitigate this issue by cooling the compressed air before it enters the engine’s intake manifold.

By lowering the temperature of the intake air, intercoolers increase its density. This denser air allows for more oxygen molecules to enter the combustion chamber, leading to improved combustion efficiency. As a result, the engine can produce more power without increasing the amount of fuel consumed, effectively improving the overall power-to-weight ratio of the vehicle.

Additionally, cooler air can reduce the likelihood of engine knock, a condition that can occur when the air-fuel mixture ignites prematurely. By preventing knock, intercoolers enable turbocharged engines to run at higher boost levels safely. This means that drivers can benefit from increased throttle response and acceleration, making the overall driving experience more exhilarating.

Moreover, intercoolers provide a temperature regulation effect. Maintaining optimal air temperatures not only increases power output but also ensures longevity of engine components. Excessive heat can lead to mechanical failures and decreased reliability; thus, intercoolers contribute to the durability of turbocharged engines as well.

In summary, intercoolers are vital in turbocharged engines as they enhance air density, prevent engine knock, and promote longevity. By effectively managing the temperature of the compressed air, intercoolers significantly improve performance, making them an essential component in high-output engine designs.

Types of Intercoolers: Choosing the Right One for Your Turbo Setup

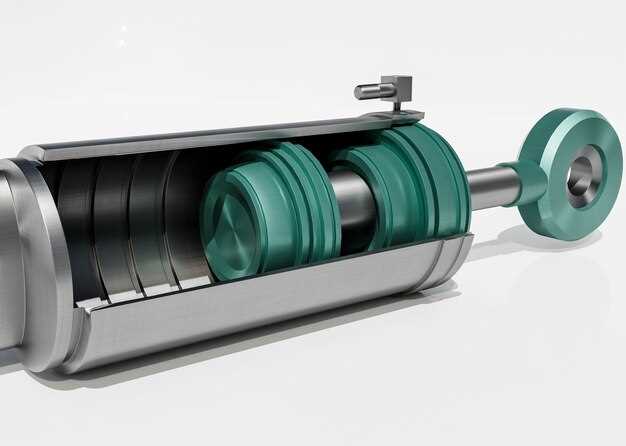

When selecting an intercooler for your turbocharged engine, understanding the different types available is crucial. The most common types of intercoolers are air-to-air and air-to-water intercoolers, each with its distinct advantages and applications.

Air-to-Air Intercooler is the most popular choice for performance vehicles. It utilizes ambient air to cool the intake charge as it passes through the intercooler core. This type is generally lightweight, allowing for minimal pressure drop and efficient cooling at higher speeds. However, its effectiveness can diminish in stop-and-go traffic where airflow is limited.

Air-to-Water Intercooler, on the other hand, uses coolant to absorb heat from the compressed air. This design allows for a more compact intercooler, making it ideal for applications where space is a constraint. Air-to-water systems tend to provide better cooling efficiency under various conditions but may require additional plumbing and a reservoir for the coolant, adding complexity and weight.

Another variant to consider is the Liquid-to-Air Intercooler, which combines aspects of both air-to-water designs. This system circulates a liquid coolant directly through the core, offering effective cooling capabilities with less airflow dependency. Its installation complexity and cost, however, might not make it suitable for every build.

When choosing an intercooler, consider the size and design. A larger intercooler can provide more cooling capacity but may also lead to increased turbo lag. Balancing these factors is essential for optimizing performance. Additionally, evaluate the material used in the intercooler’s construction; options like aluminum offer excellent thermal conductivity and lightweight properties.

Ultimately, the right intercooler for your turbo setup will depend on factors such as vehicle application, desired performance, and environmental conditions. Understanding the differences and potential trade-offs will guide you in making an informed decision that enhances your turbocharged experience.

Common Issues with Intercoolers and Their Solutions

Intercoolers play a crucial role in turbocharged engines by cooling the compressed air before it enters the engine. However, several common issues can arise with intercoolers, potentially affecting performance and reliability.

One prevalent issue is inefficiency due to clogging. Over time, dirt and debris can accumulate in the intercooler, restricting airflow and reducing cooling performance. Regular cleaning of the intercooler can help maintain its efficiency. For severe cases, a replacement might be necessary.

Another common problem is leaks in the intercooler system. These leaks can occur due to damaged hoses, cracked end tanks, or poor connections. A visual inspection followed by a pressure test can help identify leaks. Repairing or replacing the faulty components will restore proper functionality to the system.

Heat soak is also a typical concern. After prolonged use, the intercooler may become less effective at dissipating heat, leading to higher intake temperatures. Upgrading to a larger or more efficient intercooler can alleviate this problem, providing better thermal management.

Moreover, inadequate mounting can result in intercooler vibration, which might lead to damage over time. Ensuring proper mounting and using vibration-absorbing materials can mitigate this risk, maintaining the integrity of the intercooler.

Lastly, a mismatch between the intercooler and turbocharger specifications can hinder performance. It’s essential to choose an intercooler that is compatible with the turbo setup to ensure optimal air intake temperatures and enhance engine efficiency.